Fascination About Premier Aluminum Llc

Table of ContentsNot known Details About Premier Aluminum Llc Premier Aluminum Llc - QuestionsThe 15-Second Trick For Premier Aluminum LlcThe Definitive Guide to Premier Aluminum Llc

(http://peterjackson.mee.nu/where_i_work#c2475)Commonly, a buyer's main obligation was to find qualified and receptive vendors. In many cases, purchasers thought that any vendor happy to contractually fulfill the purchase need was certified. Utilizing reduced cost and unqualified vendors can cause top quality issues, and squandered time and cash in the long run. To assist you via the process, here are some points to consider when selecting the right metal casting distributor.

As an example, a firm that just utilizes the investment spreading process will certainly attempt to market you on why that process is best for your application. However what happens if using the sand casting procedure is best for you and your needs? Instead, search for a distributor that provides a series of casting processes so the ideal option for YOU is chosen

If functioning with a solitary source for all of your spreading requires is necessary to you, the vendor requires to be diverse in its capabilities. When combined with various other incorporated abilities, this can help streamline and compress the supply base. When picking the best spreading distributor, careful consideration ought to be provided to top quality, solution, and cost.

Unknown Facts About Premier Aluminum Llc

Buyers significantly pick casting distributors who have machining capabilities. If the spreading provider discovers a concern throughout machining, the issue is fixed faster with no disagreement over whose fault it is.

Trouble or no, integrated machining streamlines the supply chain and minimizes taking care of time and delivery cost prior to the product makes it to the client. What do you require from your casting provider? Are you looking for somebody to simply deliver a metal part to your front door or do you need a lot more? If you do not have in-house metallurgy know-how, validate that the supplier can provide guidance in selecting the proper alloy based on your particular application.

Others will certainly exceed the letter of the PO to help you save time and cash. Do you have requirements for both ferrous and non-ferrous alloys? Some factories are minimal or specialized. Make sure the visit our website vendor can fulfill all your product or alloy requirements to eliminate the need for several distributors.

The Best Guide To Premier Aluminum Llc

Research the distributor's web site. Talk to a sales representative or service associate. Ask a great deal of concerns. See their facility. Obtain an understanding of what they can do for you and if you can see on your own building a solid, shared relationship with them.

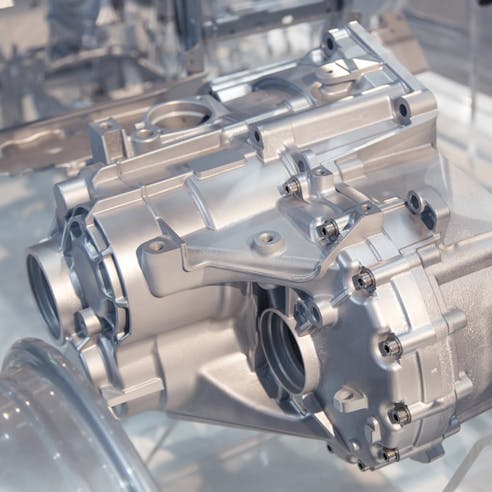

Light weight aluminum is also lightweight and has good rust resistance, making it optimal for applications where weight and toughness are very important factors. In addition, aluminum casting is an economical method of manufacturing, as it calls for less energy and sources than various other methods. Iron spreading, on the various other hand, involves putting molten iron into a mold to develop a desired shape.

Premier Aluminum Llc Can Be Fun For Everyone

Iron casting is likewise able to stand up to high temperature levels, making it ideal for usage in applications such as engine components and commercial equipment. Iron casting can be more expensive than light weight aluminum spreading due to the greater expense of raw materials and the energy called for to thaw the iron. When deciding in between light weight aluminum casting and iron casting, it is very important to consider the specific needs of the application.

In conclusion, both aluminum casting and iron casting have their very own unique benefits and downsides. There are three sub-processes that drop under the classification of die casting: gravity pass away casting (or irreversible mold casting), low-pressure die spreading and high-pressure die casting. To get to the finished item, there are three key alloys utilized as die casting product to select from: zinc, aluminum and magnesium.